Founded in the year 2001, Promattec is the company in the Sanz Group which is specialised in the design and manufacture of moulds for injection and plastic blowing.

The main services carried out at Promattec are:

- Maintenance and repair of moulds

- Construction of new moulds for blowing and injection

- Mechanising in short series.

As an added advantage, at Promattec we work closely with Agroplastic, a Group company devoted to the manufacture of plastic parts by the process of injection moulding.

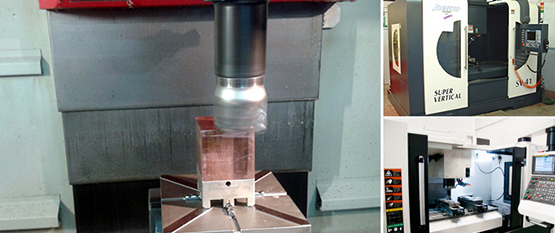

Manufacturing is done by mechanized processes for metal removal. These processes are performed by a 3D design of the piece through a CAD-CAM program, for subsequent machining.

With a group of professionals who are highly-qualified in design, mechanics, processes and who have specialist machinery, at Promattec we carry out projects at the highest levels of quality.

As an added advantage, at Promattec we work closely with Agroplastic, a Group company devoted to the manufacture of plastic parts by the process of injection moulding. This partnership reduces the time necessary for carrying out the projects, by means of process integration and taking advantage of synergies.

Specialists in plastic injection

We currently have a multidisciplinary team of 8 people with extensive experience in tooling, in addition to specialized machinery and technology that allows us to have great versatility for project development.

CONTACT OUR PROFESSIONALS

With a group of professionals who are highly-qualified in design, mechanics, processes and who have specialist machinery, at Promattec we carry out projects at the highest levels of quality.

WHY PROMATECC?

Our manufactured products, entirely in Spain, allow us to guarantee quality with European standards.

Grupo Sanz, with 65 people in the company puts in the hands of the client all the potential and experience acquired in the last 30 years.

Customers like VW, Audi, Mercadona, Monsanto, Bayer, Syngenta, BASF, MSD… trust us every year for the design and manufacture of their products.

OWN DEVELOPMENT

Every year, our Product Development Department improves our current catalog and designs new products to allow our customers to be increasingly competitive.

We have our own R&D department with more than 15 patents and industrial designs in force, which guarantees us and our clients a continuous work in cost optimization and adaptation to the new market demands.

Prototyping through 3D printing in our own facilities optimizes the design and testing, with maximum efficiency in time and costs.

FACILITIES

In our facilities we have plastic injection, where we currently have 13 injectors, ranging from 60 tons to 480 tons of pressure and that allows us to transform a wide variety of plastic compounds, and inject parts whose weight ranges between 1grs. and 1.5kgs Our clients have integral service in a single supplier: Design and manufacture of molds, preseries and production.

We know that for our customers, stock and logistics play a fundamental role. In Promattec we have 10,000 square meters in our facilities that allow us maximum efficiency in production, storage and delivery.

PROTOTIPOS Y MATRICERÍA TECNICA, SL. ha recibido por parte de la Conselleria de Economía Sostenible, Sectores Productivos, Comercio y Trabajo de la Generalitat Valenciana, la Subvención de 63.866,64 € en apoyo al proyecto INPYME/2022/780 del “Programa ayudas para mejorar la competitividad y sostenibilidad de las pymes industriales de los sectores de la Comunitat Valenciana del calzado, cerámico, metal-mecánico, textil, juguete, mármol-piedra natural y áridos, madera – mueble e iluminación, químico, automoción, plástico, envases y embalaje, papel y artes gráficas, valorización de residuos y los sectores emergentes de la biotecnología, producción audiovisual y producción de videojuegos, dentro de la cuarta fase de implantación del Plan Estratégico de la Industria Valenciana”.